Kupisa-KunyudzaKugadzira simbi(HDG) inopa kukosha kwakanyanya kwenguva refu kumapurojekiti esimbi. Chisungo chayo chakasiyana chesimbi chinopa kugara kwenguva refu kusingaenzaniswi kubva pakukuvadzwa. Maitiro ekunyudza anoita kuti chifukidzo chakazara, chakafanana icho nzira dzekupfapfaidza dzisingagoni kutevedzera. Dziviriro iyi miviri inoderedza zvakanyanya mari yekugadzirisa hupenyu hwese.

Musika wepasi rose wekusimudzira hupfumi unotarisirwa kusvika mabhiriyoni emadhora $68.89 muna 2025.mugadziri wemidziyo yemagetsiinovaka yepamusoromitsetse yekusimbisakuti zvizadzise kudiwa uku kuri kukura.

Zvinhu Zvinokosha Zvaunofanira Kuziva

- Kupisa-kunyikainoita kuti simbi isimbe zvikuru. Inogadzira chisungo chakakosha chinodzivirira simbi zviri nani kupfuura pendi.

- Kugadzira simbi nesimbi kunofukidza zvikamu zvese zvesimbi. Izvi zvinodzivirira ngura kuti isatange munzvimbo dzakavanda.

- Simbi yakarukwa inochengetedza mari nekufamba kwenguva. Inogara kwenguva yakareba uye haidi kugadziriswa zvakanyanya pane mamwe machira.

Chii Chinoita Kuti Kupisa-Dip Kuve Sarudzo Yepamusoro?

Kupisa-Dip Galvanizing (HDG) kwakasiyana nedzimwe nzira dzekudzivirira ngura. Kubudirira kwayo kunobva musimba guru resimbi: kubatana kwesimbi, kufukidza kwakazara, uye sisitimu yekudzivirira ine mabasa maviri. Zvinhu izvi zvinoshanda pamwe chete kuti zvipe kushanda kusingaenzaniswi uye kukosha kwenguva refu.

Kugara Kusingaenzaniswi Kuburikidza Nechisungo Chesimbi

Pendi nezvimwe zvinongonamira pamusoro pesimbi. Kuisa galvanizing inopisa kunoita kuti simbi ive chikamu chesimbi pachayo. Maitiro acho anosanganisira kunyudza chikamu chesimbi muzingi yakanyungudutswakupisa kusvika pa450°C (842°F). Kupisa uku kwakanyanya kunokonzera kupararira kwemvura, zvichibatanidza zinc nesimbi pamwe chete.

Maitiro aya anoumba nhevedzano yezvikamu zvakasiyana zve zinc-iron alloy. Zvikamu izvi zvinobatanidzwa nesimbi pasi pesimbi.

- Gamma Layer: Iri pedyo nesimbi, ine zinc inosvika 75%.

- Rutivi rweDelta: Danho rinotevera rinobuda, rine zinc inosvika 90%.

- Zeta Layer: Chidimbu chakakora chine zinc inosvika 94%.

- Eta Layer: Rutivi rwekunze rwezinc rwakachena runopa kupenya kwekutanga.

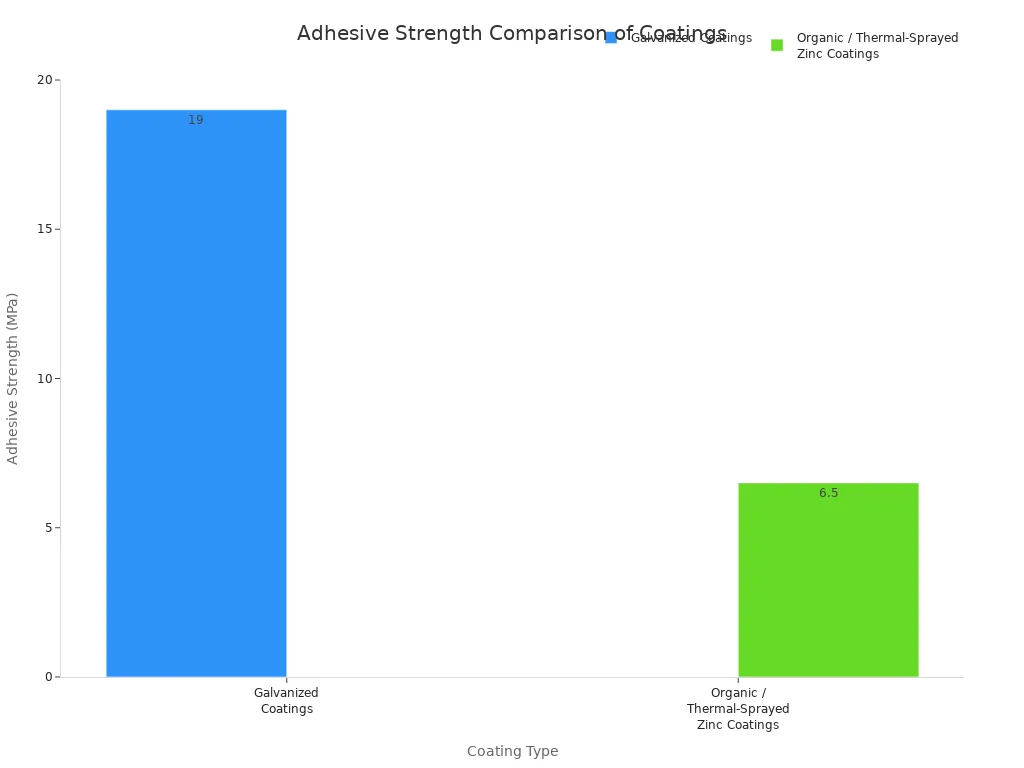

Matanda aya akabatana akaomarara kupfuura simbi yesimbi, zvichipa simba guru rekukwenya nekukuvadzwa. Matanda emukati akaomarara anodzivirira kukwenya, nepo danda rekunze rezinc rakapfava richikwanisa kunyudza kurova. Chisungo ichi chesimbi chakasimba kupfuura zvisungo zvemakanika zvemamwe machira.

| Rudzi rwekuputira | Simba reBond (psi) |

|---|---|

| Hot-Dip kwakakurudzira | ~3,600 |

| Zvimwe Zvekupfeka | 300-600 |

Simba guru iri rekubatanidza zvinhu zvinoreva kuti jira remagetsi rakaoma zvikuru kubvisa kana kupwanya. Rinogona kumira zvakanaka kana richitakurwa, kubatwa, uye kuvakwa panzvimbo yacho.

Kudzivirirwa Kwakazara Kwese

Ngura ndiyo inonyanya kushata. Mapendi ekupfapfaidza, primer

s, nezvimwe zvipfeko zvinogona kukanganisa kushandiswa kwechinhu zvakaita semadonhwe emvura, kumhanya, kana nzvimbo dzisina kufambiswa. Zvikanganiso zvidiki izvi zvinova nzvimbo dzekutanga kuita ngura.

Kuisa simbi mu "hot-dip galvanizing" kunobvisa njodzi iyi kuburikidza nekunyudza simbi yese. Kunyika simbi yese yakagadzirwa mu "metal zinc" inovimbisa kufukidza simbi yese. "Liquid zinc" inoyerera ichipinda, pamusoro, uye yakatenderedza nzvimbo dzese.

Kona yega yega, mupendero, musono, uye chikamu chemukati chine maburi chinodzivirirwa zvakaenzana. Kufukidzwa uku "kunobva kumucheto kusvika kumucheto" kunoita kuti pasave nenzvimbo dzisina kudzivirirwa dzinosiyiwa dzakatarisana nezvakatipoteredza.

Dziviriro iyi yakazara haisi nzira yakanakisisa chete; inodiwa. Mitemo yepasi rose inorayira mwero uyu wehunhu kuti ive nechokwadi chekuti inoshanda zvakanaka.

- ASTM A123inoda kuti simbi igare yakatsetseka, yakatsetseka, uye yakafanana, isina nzvimbo dzisina kuputirwa.

- ASTM A153inoisa mitemo yakafanana yemidziyo yemagetsi, ichida kuti ipedziswe zvakakwana uye zvinonamatira.

- ISO 1461ndiyo mwero wepasi rose wekuona kuti zvinhu zvakagadzirwa nesimbi zvinofukidzwa zvakakwana uye zvakaenzana.

Maitiro aya anovimbisa dziviriro inogara iripo pachivako chose, chinhu chisingakwanise kuitwa nekushandisa mabhurashi kana maspray nemaoko.

Chiito Chiviri: Chipingamupinyi uye Dziviriro Yechibayiro

Kupenda kwakarukwa kunodzivirira simbi nenzira mbiri dzine simba.

Kutanga, inoshanda sechivharo chekudzivirira. Zinc layers dzinovhara simbi kubva pakusangana nehunyoro neokisijeni. Zinc pachayo inotsungirira zvakanyanya. Munzvimbo zhinji dzemumhepo, zinc inoora nekukurumidza kagumi kusvika makumi matatu pane simbi. Kuora uku kunononoka kunopa dziviriro yemuviri inogara kwenguva refu.

Chechipiri, inopadziviriro yekuzvipiraZinc inoshanda zvakanyanya nemagetsi kupfuura simbi. Kana chifukidziro chikakuvadzwa nekukwenya kwakadzika kana gomba rekuboorera, zinc inotanga yaora, "ichizvipa mhosva" kudzivirira simbi iri pachena. Dziviriro iyi ye cathodic inodzivirira ngura kuti isapinde pasi pechifukidziro uye inogona kudzivirira nzvimbo dzisina chinhu kusvika ¼ inch mudhayamita. Zinc inoshanda semuchengeti wesimbi, ichivimbisa kuti kunyangwe chipingamupinyi chikatyorwa, chimiro chacho chinoramba chakachengeteka kubva mukuora. Iyi pfuma yekuzviporesa ibatsiro rakasiyana regalvanizing.

Maitiro eHDG: Chiratidzo Chemhando Yepamusoro

Hunhu hwakanaka hwejira rakabatidzwa nekupisa harisi tsaona. Rinobva mukuita kwakanyatsojeka, kune matanho akawanda anovimbisa kupera kwakanaka. Maitiro aya anotanga kare simbi isati yabata zinc yakanyungudutswa.

Kubva pakugadzirira pamusoro kusvika pakunyungudutswa kweZinc Dip

Kugadzirira zvakanaka pamusoro ndicho chinhu chakakosha kuti jira ribudirire. Simbi inofanira kunge yakachena zvakakwana kuti simbi iite basa rayo. Maitiro acho anosanganisira matanho matatu akakosha:

- Kubvisa mafuta: Mushonga unopisa wealkali unobvisa tsvina yeorganic yakaita setsvina, mafuta, uye mafuta kubva musimbi.

- Kusvuta: Simbi inonyikwa mubhavhu rine acid yakawanda kuti ibvise ngura neganda remugayo.

- Kufambisa mvura: Kunyudzwa kwekupedzisira mu zinc ammonium chloride solution kunobvisa chero ma oxide ekupedzisira uye kunoisa jira rinodzivirira kudzivirira ngura itsva kuti isaumbwe isati yagadzirwa.

Mushure mekucheneswa uku kwakasimba ndipo panonyudzwa simbi mubhavhu rezinc rakanyungudutswa, rinowanzo piswa kusvika pa450°C (842°F).

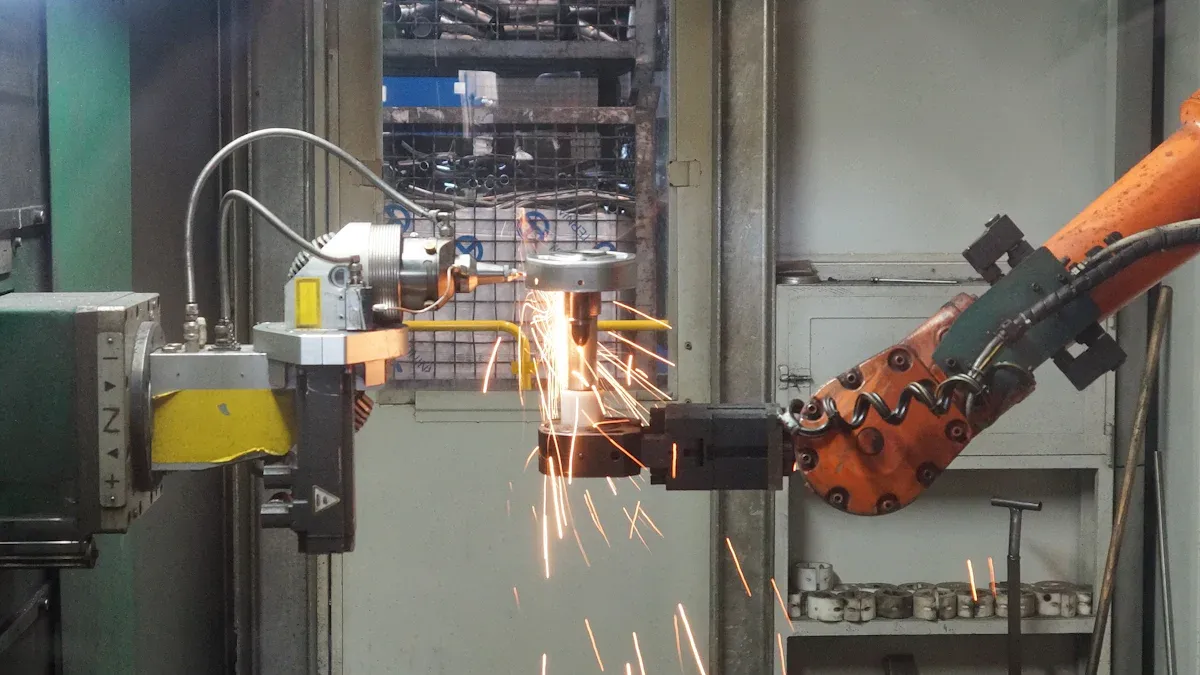

Basa reMugadziri weMidziyo yeGalvanizing

Hunhu hwese hunoenderana nemichina. Nyanzvi yekugadzira michina yemagetsi inogadzira uye inovaka mitsetse yepamusoro inoita kuti HDG yemazuva ano ikwanise kushanda. Nhasi, kambani inotungamira mukugadzira michina yemagetsi inoshandisa otomatiki uye masensa enguva chaiyo kuti itonge zvakanaka. Izvi zvinoita kuti danho rega rega, kubva pakuchenesa makemikari kusvika pakugadzirisa tembiricha, rive rakagadziridzwa. Uyezve, masisitimu ekugadzira michina yemagetsi ane mutoro anosangana nezvinodiwa zvakasimba zvekuchengetedza nharaunda, kazhinji anosanganisira masisitimu akavharwa ekugadzirisa marara. Hunyanzvi hwemugadziri wemidziyo yemagetsi hunokosha kuti pave nemigumisiro yakanaka uye yakarongeka.

Kukora Kwekuputira Kunoita Sei Kuti Ugare Hupenyu Hurefu?

Maitiro anodzorwa, anotungamirwa nemasisitimu anobva kumugadziri wemidziyo yepamusoro-soro yemagetsi, anokanganisa zvakananga ukobvu hwekupedzisira hwesimbi. Ukobvu uhwu hunoratidza hupenyu hwesimbi. Kuvhara zinc kwakakora uye kwakafanana kunopa nguva yakareba yekudzivirira uye dziviriro. Mitemo yeindasitiri inotsanangura ukobvu hwesimbi hushoma zvichienderana nerudzi nehukuru hwayo, zvichiita kuti ikwanise kumira munzvimbo yayo yakarongerwa kwemakumi emakore pasina kugadziriswa kwakawanda.

HDG vs. Dzimwe Nzira: Kuenzanisa Kwekushanda Kwa2025

Kusarudza sisitimu yekudzivirira ngura kunoda kunyatsoongorora mashandiro ayo, kugara kwenguva refu, uye mutengo wayo kwenguva refu. Kunyange zvazvo paine dzimwe nzira dzakawanda,kunyudza nekupisainogara ichiratidza kunaka kwayo kana ichienzaniswa zvakananga nemapendi, maepoxies, uye maprimer.

Kupesana nePendi neEpoxy Coatings

Pendi ne epoxy coatings imhando yemafirimu epamusoro. Zvinogadzira jira rinodzivirira asi hazvibatanidzi simbi nemakemikari. Musiyano uyu mukuru unotungamira pakushanda kwakakura.

Mapendi epoxy anonyanya kukundikana. Anogona kutsemuka nekusvuuka, zvichiratidza simbi iri pasi payo. Kana chipingamupinyi chatyoka, ngura inogona kupararira nekukurumidza. New York State Thruway Authority yakadzidza izvi pachayo. Pakutanga vakashandisa rebar ine epoxy-coated pakugadzirisa migwagwa, asi mapendi acho akakurumidza kutsemuka. Izvi zvakaita kuti migwagwa itsakatike. Mushure mekushandura kune galvanized rebar pakugadzirisa bhiriji, mhedzisiro yacho yaishamisa zvekuti ikozvino vanoshandisa galvanized materials kumapurojekiti avo.

Kusakwana kwe epoxy coatings kunova pachena kana tichienzanisa ne HDG.

| Chinhu | Kuputira kweEpoxy | Kupisa-Kunyudza |

|---|---|---|

| Kubatana | Inogadzira firimu pamusoro; hapana chisungo chemakemikari. | Inogadzira chisungo chemakemikari, chesimbi nesimbi. |

| Maitiro Ekukundikana | Inowanzotsemuka uye kudonha, izvo zvinoita kuti ngura ipararire. | Hunhu hwekuzvirapa hunochengetedza mavanga uye hunodzivirira ngura kupinda. |

| Kugara kwenguva refu | Inogona kutsemuka zviri nyore panguva yekutakura nekuisa. | Zvidimbu zve alloy zvakasimba kwazvo zvinodzivirira kukweshwa kana kukuvadzwa. |

| Kugadzirisa | Hapana kugona kuzvigadzirisa wega. Nzvimbo dzakakuvara dzinofanira kugadziriswa nemaoko. | Inodzivirira otomatiki nzvimbo diki dzakakuvara kuburikidza nechiito chekuzvipira. |

Kushandisa uye kuchengetedza zvinopawo matambudziko makuru ekushandisa epoxy coatings.

- Njodzi Yekukuvara: Epoxy inopwanyika. Kukwenya panguva yekutakura kana kuisa kunogona kukonzera ngura isina simba.

- Kunzwa kweUV: Simbi yakaputirwa ne epoxy inoda ma tarps akakosha ekuchengetera panze. Inofanira kugara yakavharwa kudzivirira kukuvara kubva kuzuva.

- Kurasikirwa kweAdhesion: Kubatana kwesimbi nejira repurasitiki kunogona kupera simba nekufamba kwenguva, kunyangwe kana yachengetwa.

- Nzvimbo dzeGungwa: Munzvimbo dziri kumahombekombe, machira e epoxy anogona kushanda zvakaipa kupfuura simbi isina chinhu. Munyu nehunyoro zvinoshandisa nyore nyore chero zvikanganiso zvidiki zviri mujira racho.

Munzvimbo dziri kumahombekombe, HDG inoratidza kusimba kwayo. Kunyangwe munzvimbo dzine mhepo ine munyu wakananga, simbi yakarukwa inogona kugara kwemakore mashanu kusvika manomwe isati yatanga kugadziriswa. Nzvimbo dzakadzivirirwa pachivako chimwe chete dzinogona kuramba dzakachengetedzwa kwemakore gumi nemashanu kusvika makumi maviri nemashanu.

Kurwisa MaPrimer Akapfuma muZinc

Ma primer ane zinc yakawanda anowanzo shandiswa senzira yemvura panzvimbo pe galvanizing. Ma primer aya ane guruva re zinc rakasanganiswa mu pendi. Zvidimbu zve zinc zvinopa dziviriro, asi sisitimu yacho inoenderana nekubatana kwemuchina, kufanana nependi yenguva dzose.

Kusiyana neizvi, kupisa-kunyika, kunogadzira mativi ayo ekudzivirira kuburikidza nekuita kwekuparadzira pakupisa kwakanyanya. Izvi zvinoumba zvidimbu zvechokwadi zve zinc-iron zvinosanganiswa nesimbi. Chishandiso chine zinc yakawanda chinongonamira pamusoro. Musiyano uyu mukusungana ndiwo kiyi yekushanda kwepamusoro kweHDG.

Chinhu Kupisa-Kunyudza Primer Yakapfuma neZinc Maitiro Chisungo chesimbi chinogadzira zvidimbu zve zinc-iron alloy zvakasimba. Guruva rezinki riri mubhandi rinopa dziviriro yekuzvipira. Kunamatira Yakabatana nesimbi ine simba rekubatanidza re ~3,600 psi. Kubatana kwemuchina kunoenderana nekuchena kwenzvimbo; kusimba zvakanyanya. Kugara kwenguva refu Zvidimbu zve alloy zvakasimba kwazvo zvinodzivisa kukweshwa uye kukuvadzwa. Pendi yakapfava inogona kukwenywa kana kuchekwa zviri nyore. Kukodzera Yakanakira simbi yekuvaka kana ichishanda nesimba uye kwenguva refu. Zvakanakisa pakugadzirisa kana kana HDG isingagoneke. Kunyange zvazvo ma primer ane zinc yakawanda achidzivirira zvakanaka, haakwanise kuenzana nekusimba uye kugara kwenguva refu kwe galvanized coating chaiyo. Kushanda kwe primer kunoenderana nekugadzirwa uye kushandiswa kwakakwana kwenzvimbo, uye inoramba iri panjodzi yekukwenywa uye kukuvara kwemuviri.

Kugadzirisa Kutsoropodzwa Kwakajairika kweHDG

Pfungwa isiriyo pamusoro pekuti galvanizing inonyudzwa mumvura inopisa inyaya yekuti inodhura sei pakutanga. Kare, HDG dzimwe nguva yaionekwa senzira inodhura zvikuru pakutanga. Zvisinei, izvozvo hazvichaitiki muna 2025.

Nekuda kwemitengo ye zinc yakagadzikana uye mashandiro anoshanda zviri nani, HDG ikozvino yava kukwikwidzana zvakanyanya pamutengo wekutanga. Kana tichifunga nezvemutengo wehupenyu hwese, HDG inowanzova sarudzo inodhura zvakanyanya. Mamwe masisitimu anoda kugadziriswa nguva nenguva uye kushandiswazve, zvichiwedzera mari yakawanda muhupenyu hwepurojekiti.

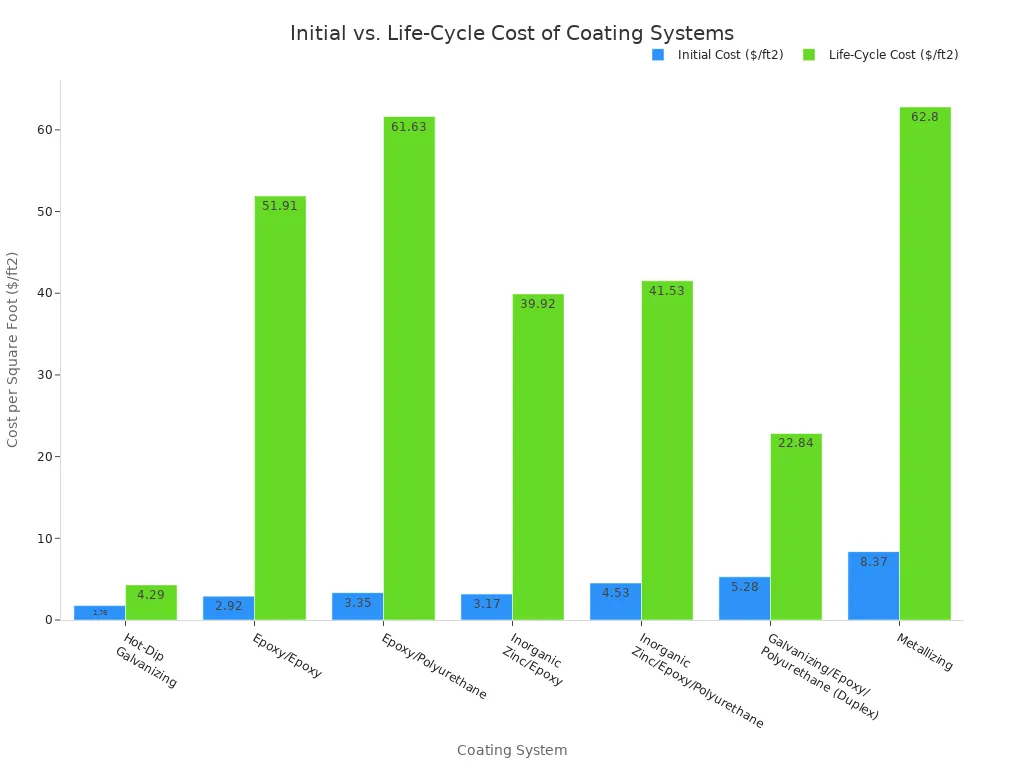

Mufananidzo Unobva:statics.mylandingpages.co Sangano reAmerican Galvanizers Association rinopa Life-Cycle Cost Calculator (LCCC) inoenzanisa HDG nedzimwe nzira dzinopfuura makumi matatu. Ruzivo urwu runoratidza nguva dzose kuti HDG inochengetedza mari. Semuenzaniso, mune imwe ongororo yebhiriji rine hupenyu hwekugadzira hwemakore makumi manomwe nemashanu:

- Kupisa-Kunyudzayaive nemari yehupenyu hwese$4.29 pa square foot.

- AnEpoxy/Polyurethanehurongwa hwacho hwaive nemutengo wehupenyu hwese$61.63 pa square foot.

Musiyano mukuru uyu unobva pakushanda kweHDG pasina kugadzirisa. Chivako chakagadzirwa nesimbi chinogona kugara kwemakore makumi manomwe nemashanu kana kupfuura pasina basa guru. Izvi zvinoita kuti ive mari yakanakisisa yekudyara mumapurojekiti enguva refu.

Nguva yekutumira: Gumiguru-28-2025