Chigadzirwa chemagetsi chinoshandisa masisitimu matatu makuru. Masisitimu aya anoshanda kugadzirira, kuputira, uye kupedzisa simbi. Maitiro aya anoshandisa maturusi akasarudzika akadai seZvishandiso zveGalvanizing zveChikamu cheMaumbirwouyeZvikamu Zvidiki zveGalvanizing mitsetse (Robort)Musika wemagetsi wakanyura zvakanyanya unoratidza mukana mukuru wekukura.

| Chikamu cheMusika | Gore | Saizi yeMusika (Mabhiriyoni eUSD) | Gore Rinofungidzirwa | Saizi Yemusika Inofungidzirwa (Mabhiriyoni eUSD) |

|---|---|---|---|---|

| Kunyudzwa neGlavanizing Inopisa | 2024 | 88.6 | 2034 | 155.7 |

Zvinhu Zvinokosha Zvaunofanira Kuziva

- Chigadzirwa chemagetsi chine nzira nhatu huru: kugadzirisa simbi isati yagadzirwa, kugadzirisa simbi mushure mekugadzirwa. Nzira idzi dzinoshanda pamwe chete kuchenesa, kuputira, uye kupedzisa simbi.

- Sisitimu yekuchenesa simbi isati yagadzirwa inobvisa tsvina, mafuta, uye ngura. Danho iri rinobatsira zinc kunamira zvakanaka pasimbi.

- Iyosisitimu yekusimbisa magiyainoisa zinc coating pasimbi. Sisitimu yekurapa mushure mekugadzirisa inotonhodza simbi uye inowedzera jira rekudzivirira rekupedzisira. Izvi zvinoita kuti simbi ive yakasimba uye inogara kwenguva refu.

Sisitimu 1: Sisitimu Yekurapwa Pamberi

Sisitimu yePre-Treatment ndiyo danho rekutanga uye rakakosha zvikuru mumaitiro ekugadzira magasiBasa rayo guru nderekugadzira pamusoro pesimbi yakachena zvakakwana. Pamusoro pakachena panoita kuti zinc igadzire chisungo chakasimba, chakafanana nesimbi. Iyi sisitimu inoshandisa nzira dzakasiyana dzekubvisa tsvina yese.

Matangi Ekubvisa Mafuta

Kubvisa mafuta ndiyo danho rekutanga rekuchenesa. Zvikamu zvesimbi zvinosvika pachirimwa zvine tsvina yepamusoro yakaita semafuta, tsvina, uye mafuta. Kubvisa mafuta mumatangi kunobvisa zvinhu izvi. Matangi ane mishonga inobvisa tsvina. Mhinduro dzakajairika dzinosanganisira:

- Mhinduro dzekubvisa mafuta eAlkaline

- Mhinduro dzekubvisa mafuta muacidic

- Zvinobvisa mafuta ealkaline pakupisa kwakanyanya

KuNorth America, ma galvanizer mazhinji anoshandisa sodium hydroxide inodziya. Vanoshandisa matangi aya e alkaline vanowanzo pisa kusvika pakati pe 80-85 °C (176-185 °F). Tembiricha iyi inovandudza kushanda kwekuchenesa pasina mari yakawanda yekufashaidza mvura.

Matangi Ekuchenesa

Mushure mekushandisa makemikari ese, simbi inoendeswa kutangi rekusukurudza. Kusukurudza kunosuka chero makemikari asara kubva mutangi rekare. Danho iri rinodzivirira kusvibiswa kwebhavhu rinotevera munhevedzano. Kusukurudza kwakakodzera kwakakosha kuti ripedzwe zvakanaka.

Mutemo weIndasitiri:Zvinoenderana neSSPC-SP 8 Pickling Standard, mvura yekusuka inofanira kunge yakachena. Huwandu hweasidhi kana munyu wakanyungudika unotakurwa uchipinda mumatangi ekusuka haufanirwe kudarika magiramu maviri pa litre.

Matangi Ekuunganidza Asidhi

Tevere, simbi inoiswa mutangi rekugadzira acid. Tangi iri rine mhinduro yeacid yakasanganiswa, kazhinji hydrochloric acid. Basa reacid nderekubvisa ngura nechiyero chemugayo, izvo zviri ma iron oxides pamusoro pesimbi. Maitiro ekugadzira anoburitsa simbi isina chinhu, yakachena iri pasi, zvichiita kuti igadzirire danho rekupedzisira rekugadzirira.

Matangi Ekufambisa Mvura

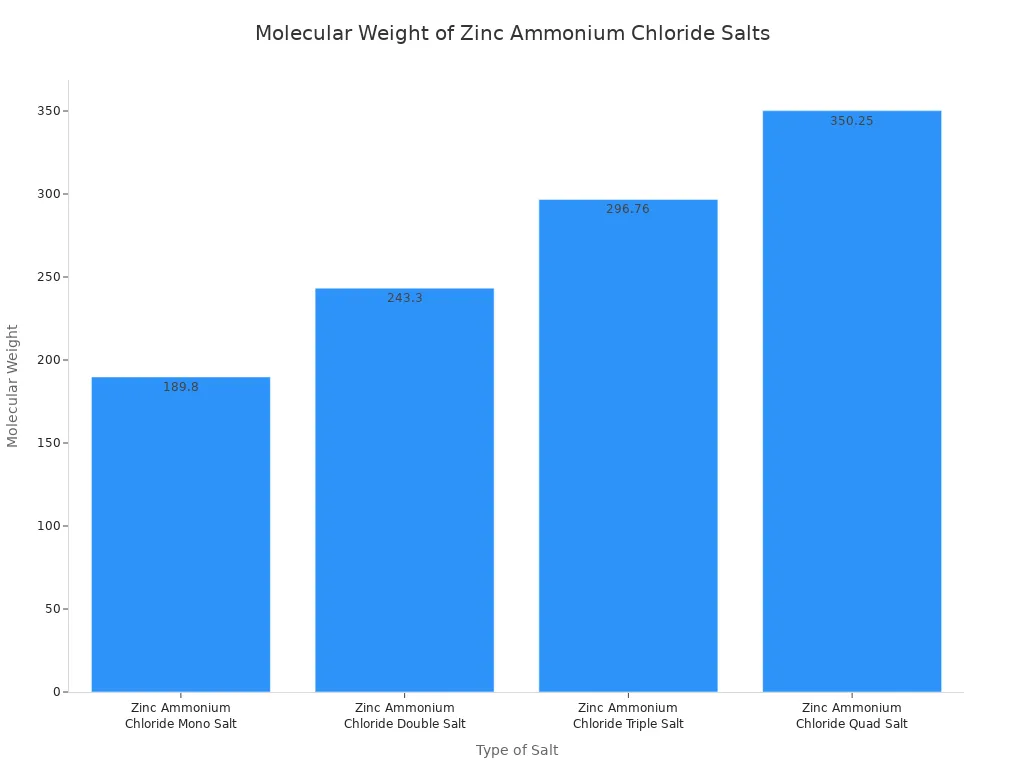

Kuchenesa ndiro danho rekupedzisira pakugadzirira usati watanga. Simbi yakachena inonyura mutangi rekufambisa mvuraine mhinduro ye zinc ammonium chloride. Mhinduro iyi inoisa jira rekudzivirira re crystalline kusimbi. Iri jira rinoita zvinhu zviviri: rinochenesa simbi zvishoma uye rinodzivirira simbi kubva ku oxygen iri mumhepo. Firimu iri rekudzivirira rinodzivirira ngura itsva kuti isaumbwe simbi isati yapinda muketero ye zinc inopisa.

Mufananidzo Unobva:statics.mylandingpages.co Sisitimu 2: Sisitimu yeGalvanizing

Mushure mekugadzirisa simbi, simbi inoendeswa kuGalvanizing System. Chinangwa chesystem iyi ndechekushandisazinc yekudzivirira. Ine zvikamu zvikuru zvitatu: ovheni yekuomesa, choto chemagetsi, uye ketero yezinc. Zvikamu izvi zvinoshanda pamwe chete kugadzira chisungo chesimbi pakati pesimbi nezinc.

Ovheni yekuomesa

Ovheni yekuomesa ndiyo nzvimbo yekutanga muhurongwa uhwu. Basa rayo guru nderekuomesa simbi zvachose mushure mekunge yatanga kuyerera. Vashandi vanowanzo pisa ovheni kusvika pa200°C (392°F). Tembiricha iyi yepamusoro inobvisa hunyoro hwese hwasara. Maitiro ekuomesa akakosha nekuti anodzivirira kuputika kwemhepo mu zinc inopisa uye anodzivirira zvikanganiso zvekufukidza zvakaita semaburi emapini.

Maovheni ekuomesa emazuva ano ane magadzirirwo anochengetedza simba. Izvi zvinoderedza kushandiswa kwemafuta uye zvinovandudza kushanda zvakanaka kwemiti.

- Vanogona kushandisa magasi anobuda muchoto kuti vapise simbi.

- Kazhinji zvinosanganisira masisitimu ekudzoreredza kupisa.

- Vanovimbisa kugoverwa kwekupisa kwakaringana uye kwakaringana.

Vira reGalvanizing

Chitofu chinobatidza simbi chinopa kupisa kwakanyanya kunodiwa kuti zinc inyunguduke. Aya mayuniti ane simba anokomberedza zinc kettle uye anochengetedza zinc yakanyungudutswa patembiricha chaiyo. Mafurnace anoshandisa matekinoroji epamusoro-soro ekupisa kuti ashande zvakanaka. Mhando dzakajairika dzinosanganisira:

- Zvipisi Zvinopisa Zvinopisa Nesimba Repamusoro

- Mavira ekupisa asina kunanga

- Mavira emagetsi

Kuchengetedzwa Kutanga: Mafurnace anoshanda pakupisa kwakanyanya, zvichiita kuti kuchengetedzeka kuve kwakakosha. Akavakwa ne insulation inodziya tembiricha yepamusoro, masensa edhijitari ekutarisa tembiricha yekettle, uye magadzirirwo anobvumira kuongororwa kuri nyore kwemaburner nemavalvu ekudzora.

Keturu yeZinc

Ketero yezinc ndiro mudziyo mukuru, wakaita sedenderedzwa unotakura zinc yakanyungudutswa. Inogara zvakananga mukati mechoto chemagetsi, icho chinoidziisa. Ketero inofanira kunge yakasimba zvikuru kuti ikwanise kutsungirira tembiricha dzakanyanya uye hunhu hwezinc yemvura inoparadza. Nekuda kweizvi, vagadziri vanogadzira maketero kubva kusimbi yakakosha, ine kabhoni shoma, isina silicon yakawanda. Mamwe anogonawo kunge aine mukati mezvidhinha zvinoramba kushanda kwenguva refu.

Sisitimu 3: Sisitimu yeMushure meKurapwa

Sisitimu yePost-Repairment ndiyo danho rekupedzisira mumaitiro ekugadzira magasiChinangwa chayo ndechekutonhodza simbi ichangobva kuputirwa uye kuisa jira rekudzivirira rekupedzisira. Sisitimu iyi inoita kuti chigadzirwa chive nechitarisiko chaunoda uye chigare kwenguva refu. Zvikamu zvikuru matangi ekudzima uye nzvimbo dzekufambisa mvura.

Matangi Ekudzima

Mushure mekubuda muketero ye zinc, simbi ichiri kupisa zvakanyanya, inenge 450°C (840°F). Kudzima matangi kunotonhodza simbi nekukurumidza. Kutonhora uku nekukurumidza kunomisa kuita kwesimbi pakati pe zinc nesimbi. Kana simbi ikatonhorera zvishoma nezvishoma mumhepo, kuita uku kunogona kuenderera mberi, zvichikonzera kupera kusina kujeka, kwemavanga. Kudzima kunobatsira kuchengetedza chitarisiko chakajeka uye chakafanana. Zvisinei, mamwe magadzirirwo esimbi haana kukodzera kudzimwa nekuti kuchinja kwekushisa nekukurumidza kunogona kukonzera kutenderera.

Vashandi vanoshandisa zvinwiwa zvakasiyana-siyana, kana kuti nzira dzekushandisa, pakudzimisa mvura zvichibva pane zvinodiwa:

- Mvura:Inotonhodza nekukurumidza asi inogona kugadzira munyu we zinc unobviswa pamusoro.

- Mafuta:Tonhodza simbi zvishoma pane mvura, izvo zvinoderedza njodzi yekutsemuka ukuwo zvichivandudza ductility.

- Munyu Wakanyungudutswa:Inopa mwero wekutonhodza unononoka uye unodzorwa zviri nani, zvichideredza kukanganiswa.

Passivation uye Kupedzisa

Kubvisa ngura (passivation) ndiko kurapwa kwekupedzisira kwemakemikari. Maitiro aya anoshandisa jira rakatetepa, risingaonekwe pamusoro pesimbi yakabatidzwa. Rudzi urwu runodzivirira zinc coating itsva kubva mukuora kwesimbi isati yasvika uye kuumbwa kwe "ngura chena" panguva yekuchengetwa nekutakurwa.

Ziviso yeKuchengetedzeka neZvakatipoteredza:Kare, passivation yaiwanzoshandisa zvinhu zvine hexavalent chromium (Cr6). Zvisinei, kemikari iyi ine chepfu uye inokonzera kenza. Masangano ehurumende akaita seUS Occupational Safety and Health Administration (OSHA) anotonga kushandiswa kwayo zvakasimba. Nekuda kwezvinetso izvi zvehutano nezvakatipoteredza, indasitiri iyi ikozvino inoshandisa zvakanyanya dzimwe nzira dzakachengeteka, dzakadai setrivalent chromium (Cr3+) uye chromium-free passivators.

Danho rekupedzisira iri rinovimbisa kutichigadzirwa chakabatidzwainosvika kwairi kuenda yakachena, yakachengetedzwa, uye yakagadzirira kushandiswa.

Masisitimu Ekutsigira Akakosha Mumiti Yose

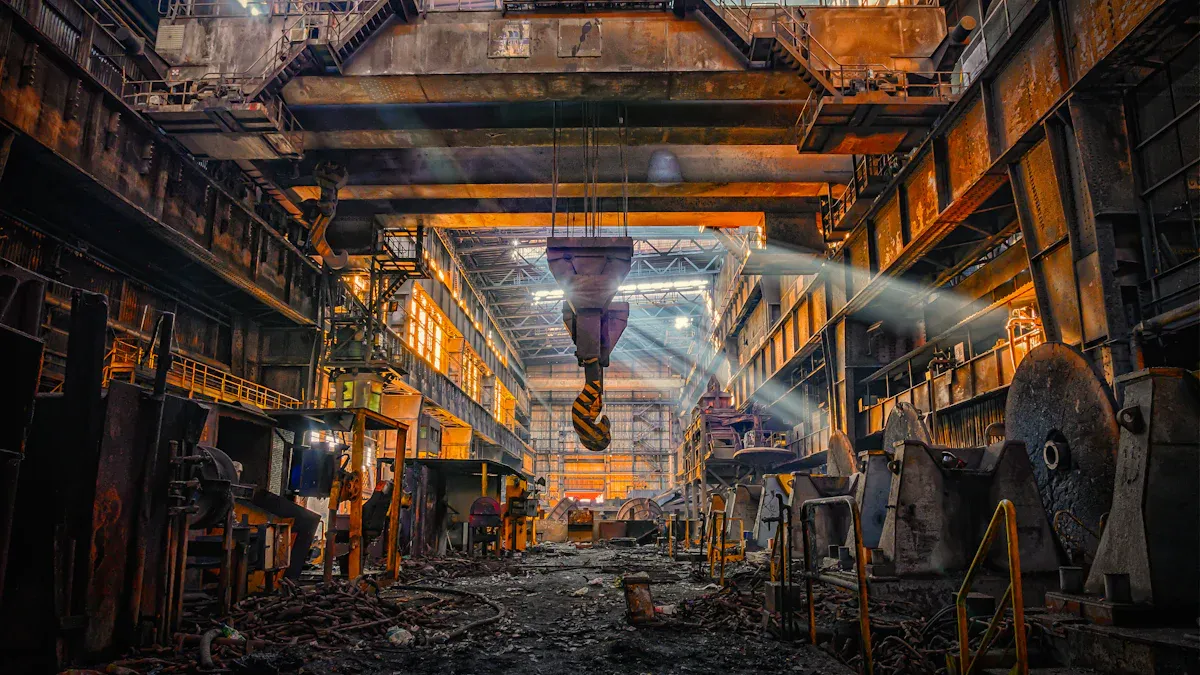

Masisitimu matatu makuru ari mufekitori inosimbisa simbi anoshandisa masisitimu akakosha ekutsigira kuti ashande zvakachengeteka uye zvinobudirira. Masisitimu aya efekitori yese anobata kufamba kwezvinhu, mabasa ekugadzira machira, uye kuchengetedzeka kwezvakatipoteredza. Anobatanidza maitiro ese kubva pakutanga kusvika pakupera.

Sisitimu Yekubata Zvinhu

Sisitimu yekubata zvinhu inofambisa zvigadzirwa zvesimbi zvinorema munzvimbo yese. Mafekitori emazuva ano ekugadzira magasi anoda makireni emhando yepamusoro nezvimwe zvishandiso kuti atarisire mashandiro ebasa. Midziyo iyi inofanira kubata huremu hwezvinhu uye kutsungirira kupisa kwakanyanya uye kusvibiswa nemakemikari.

- Makireni

- Zvikwiriso

- Matunhu ekutakura zvinhu

- Vanosimudza

Vashandi vanofanira kufunga nezve mutoro wepamusoro wemuchina uyu. Kana paine zvinhu zvinorema zvakanyanya, zvakanaka kubvunza galvanizer kuti ive nechokwadi chekuti sisitimu yavo inogona kutakura huremu. Kuronga uku kunodzivirira kunonoka uye kunoita kuti kubatwa kwakachengeteka.

Zvishandiso zveGalvanizing zveChikamu cheMaumbirwo

Zvinoshandiswa nezvirimwaZvishandiso zveGalvanizing zveChikamu cheMaumbirwokuti pave ne zinc coating yakafanana pazvinhu zvikuru kana zvakaoma. Kunyudza kwakajairika kungasakwana zvidimbu zvine maumbirwo asina kurongeka kana pamusoro pemukati. Midziyo iyi yakasarudzika inoshandisa matekiniki epamusoro, akadai sekufamba kwezvikamu zvinodzorwa kana masisitimu ekuzvipfapfaidza otomatiki, kuve nechokwadi chekuti zinc yakanyungudutswa inosvika pamusoro pese zvakaenzana. Kushandisa Structural Component Galvanizing Equipment yakakodzera kwakakosha pakusangana nezvinodiwa zvemhando yepamusoro pazvinhu zvakaita sematanda makuru kana magungano akaomarara. Kushandiswa nemazvo kweStructural Component Galvanizing Equipment kunovimbisa kupera kwakasimba uye kunodzivirira.

Kubvisa Utsi uye Kurapa

Maitiro ekugadzira galvanizing anogadzira utsi, kunyanya kubva mumatangi ekuunganidza acid uyeketero inopisa ye zincSisitimu yekubvisa utsi nekuchenesa utsi yakakosha pakuchengetedzwa kwevashandi nekuchengetedzwa kwezvakatipoteredza. Sisitimu iyi inotora utsi hunokuvadza kubva kwahunobva, yochenesa mhepo kuburikidza nemascrubbers kana mafirita, yozoiburitsa zvakachengeteka.

Kuchengetedzeka & Zvakatipoteredza:Kubvisa utsi zvinobudirira kunodzivirira vashandi kubva mukufema utsi hwemakemikari uye kunodzivirira kuburitswa kwezvinosvibisa mumhepo, zvichiita kuti chirimwa ichi chitevedzere mitemo yezvakatipoteredza.

Chigadzirwa che "turn-key galvanizing" chinobatanidza masisitimu matatu makuru. Kugadziriswa kusati kwaitwa kunochenesa simbi kuti irambe ichinamira zinc. Sisitimu ye "galvanizing" inoshandisa "coating", uye mushure mekugadzirisa inopedzisa chigadzirwa. Masisitimu ekutsigira, kusanganisira Structural Component Galvanizing Equipment, anobatanidza maitiro ese. Masisitimu emazuva ano anoshandisa otomatiki uye zviratidzo zvikuru zvekushanda kuti awedzere kushanda zvakanaka uye kuchengetedzeka.

Nguva yekutumira: Mbudzi-03-2025